The development board of air quality detection module (U-air hardware PCB) can upload the data collected by the sensors of temperature, humidity and PM2.5 to the server via GRPS. Clients can view the data through web page or APP. At present, there are interface of temperature sensor, humidity sensor and PM2.5 sensor on the PCB board (PM2.5 sensor is not standard, pls buy if required). You can install it directly on PCB board, temperature and humidity sensor is recommended to install for extension to ensure numerical accuracy.

With the development board, we can provide relevant GPRS module manual profile, circuit schematic PDF file and experimental STM32 single-chip microcomputer example program. And get the secondary development carried on conveniently.

The default parts of the development board:

Development board: 1 piece

Epitaxial temperature sensor: 1 piece

Epitaxial humidity sensor: 1 piece

Power adapter: 1 piece

And complete single-chip microcomputer project source code

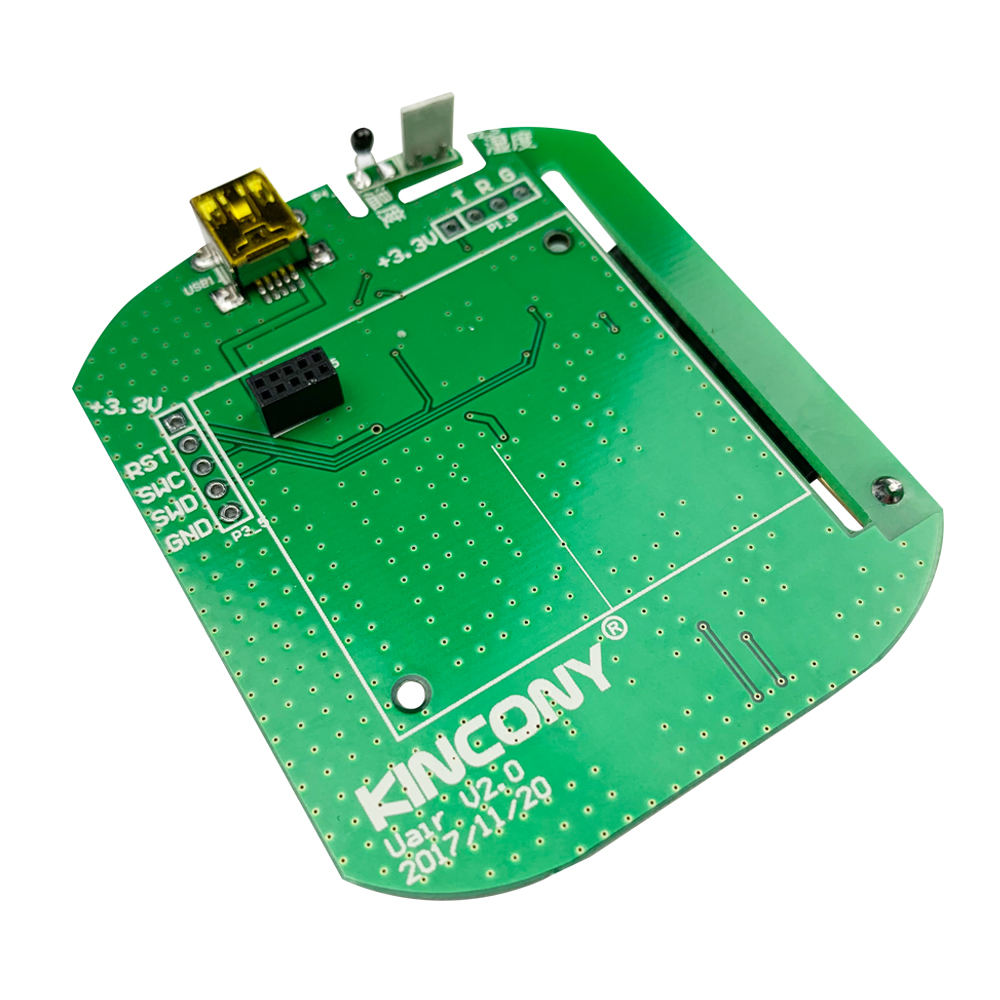

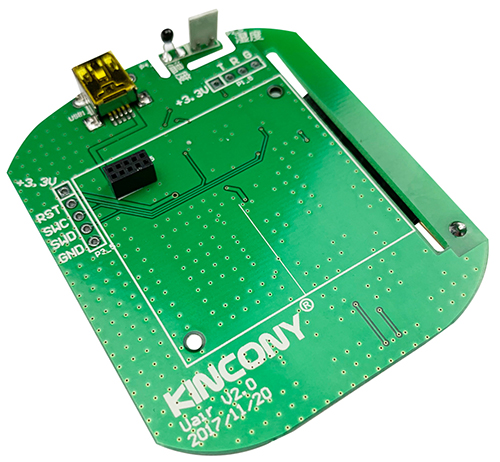

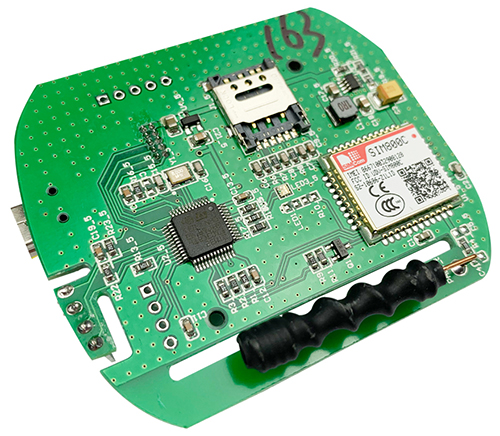

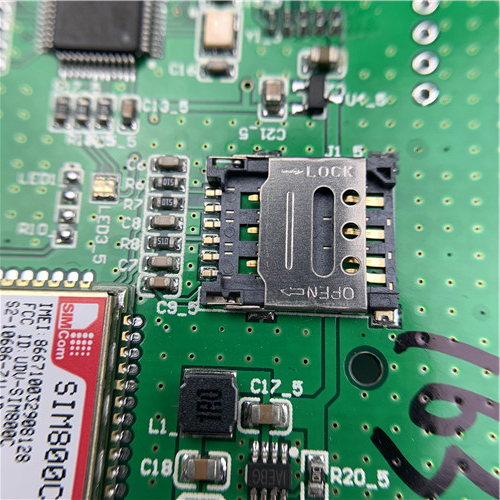

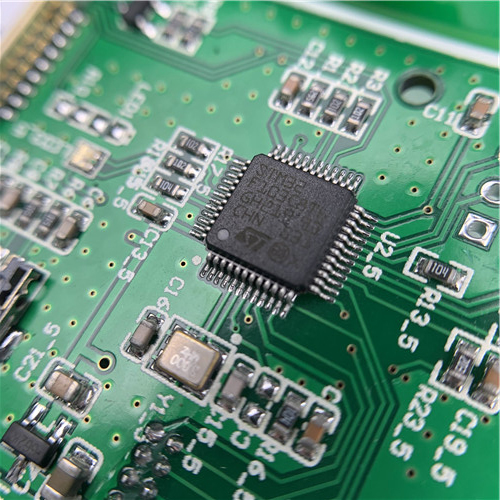

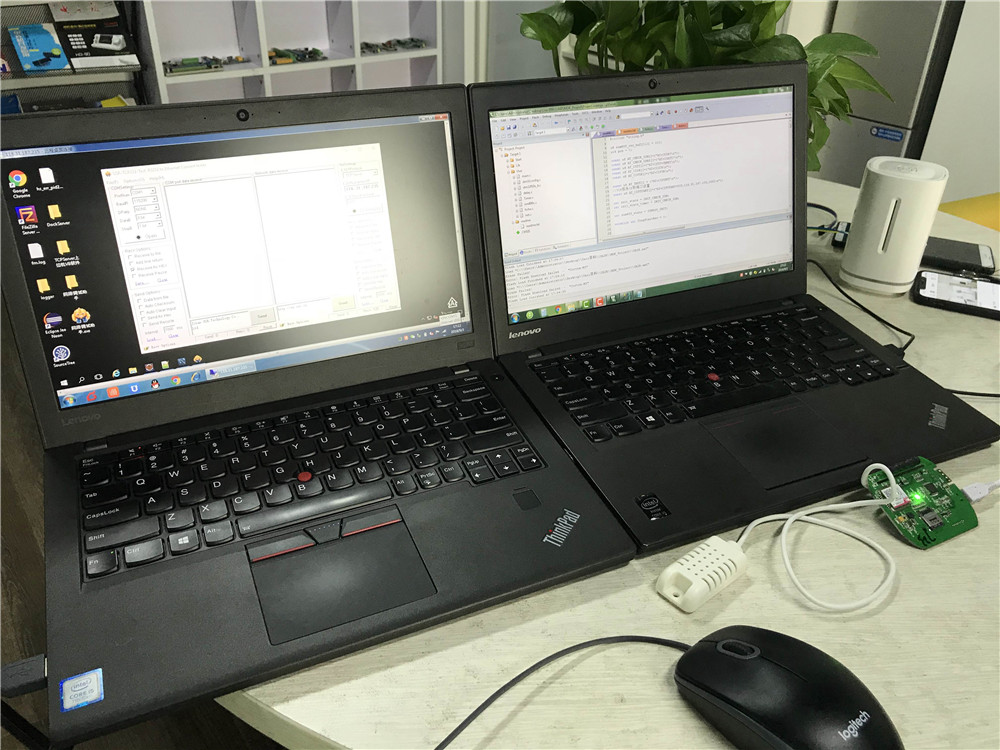

Detail Drawing of the Development Board

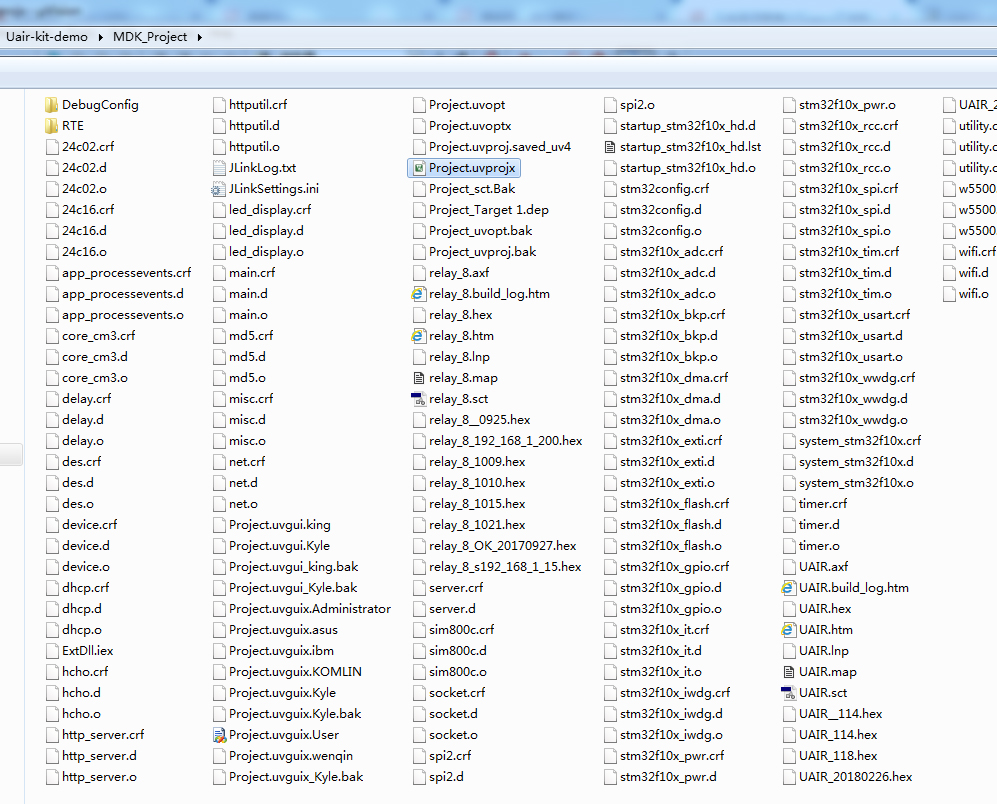

Information of the software source code

Software debugging method: by programming the software for the chip, clients can directly send the data collected by the sensors back to their own cloud server.

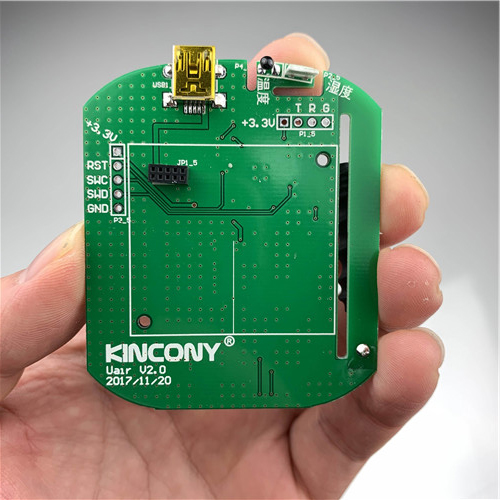

The development board is made relatively small as the above picture showed, the white part is the temperature and humidity sensor probe. There are many probes with a variety of different configuration specifications, such as for air, but also for liquid water temperature sensor probe.

These are the hardware PCB and the shell for it.

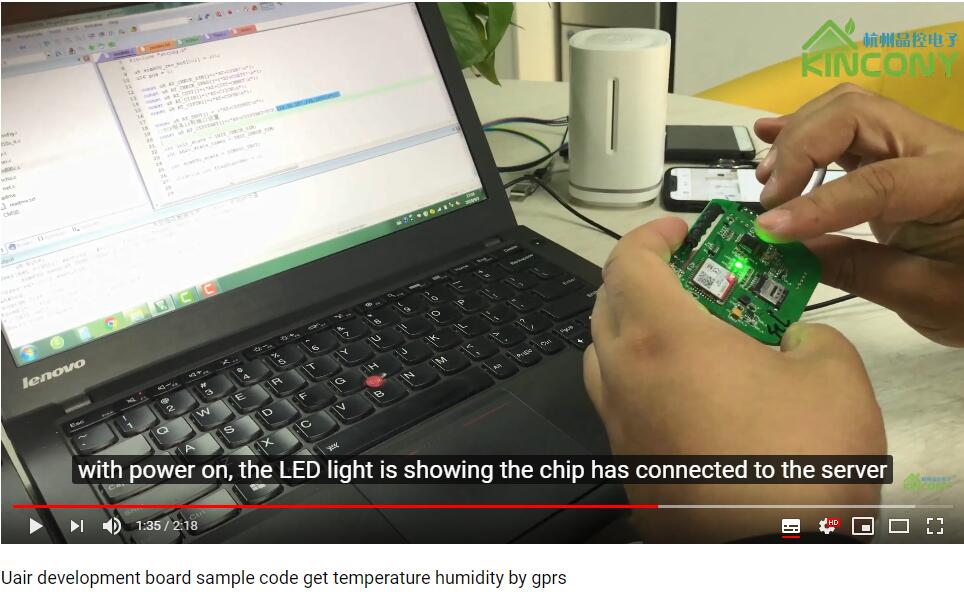

In order to make it easy for developers to reference and learn, we have made a real video.

You can see YouTube online video at : https://youtu.be/7lPDeLTgh5Q

You can see YouTube online video at : https://youtu.be/qMKimc07lSs

Let’s take a look at how to use the second way of secondary development to program chip software and transfer the underlying data to a specified cloud server.

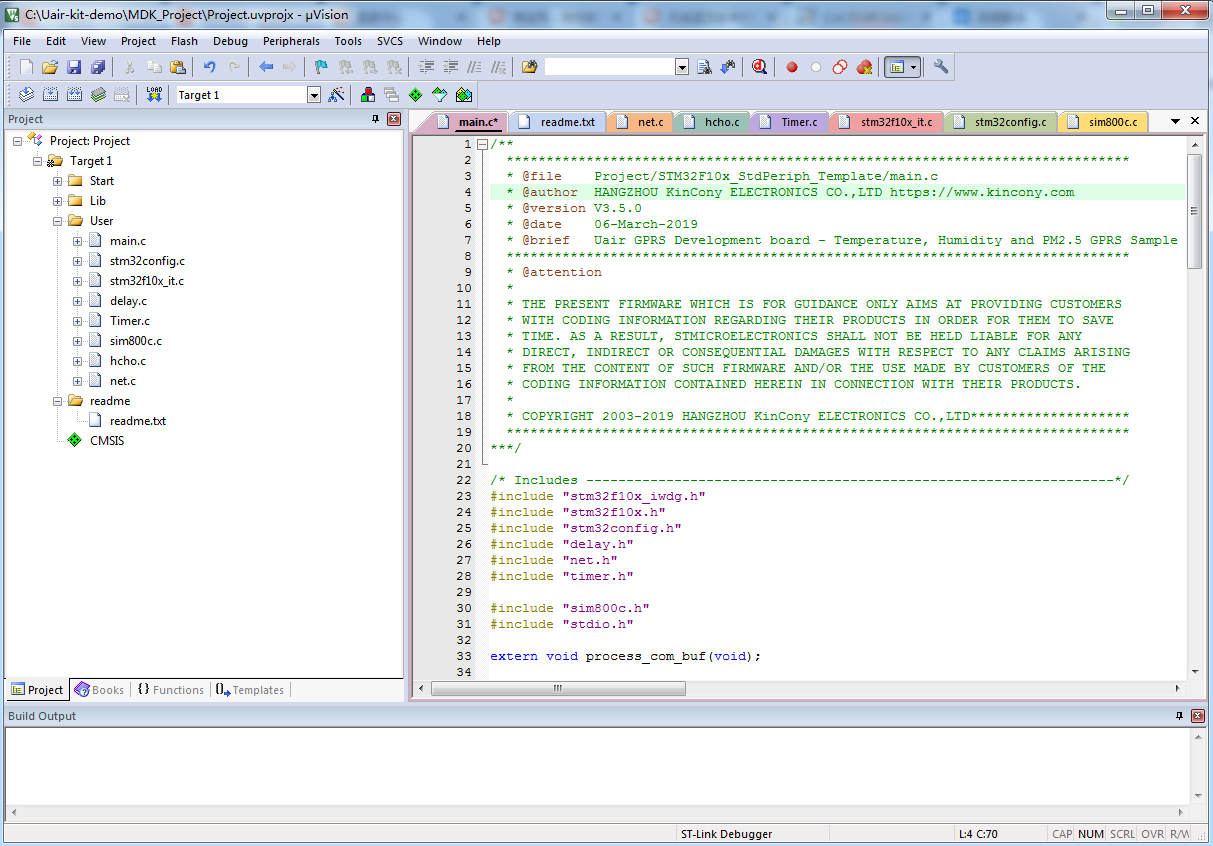

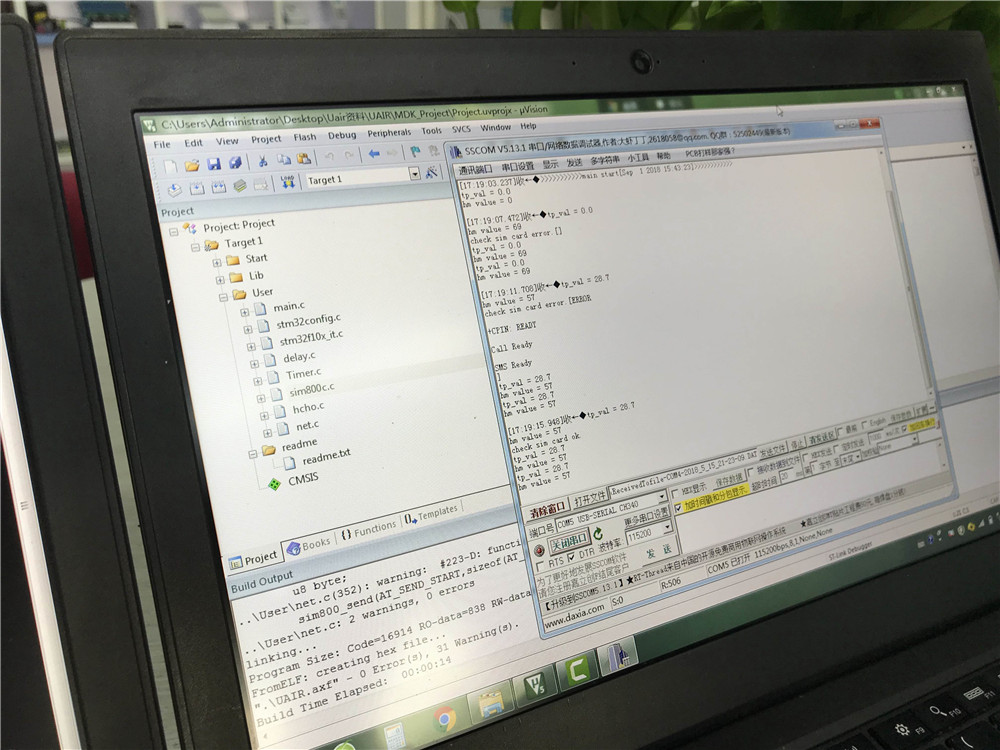

We can use KEIL5 embedded development tools to program, we have developed for you the source code of the entire “DEMO” project.

(If need KEIL software, you can download or learn about the purchase information from the website. The routines and materials provided by this site are for learning and reference only)

We have finished the program of the data acquisition and the AD-to-Digital conversion, meanwhile, our engineer has made detail comments for some key program code, so that the developer can understand clearly. The whole project document can be opened directly to complete the compiling.

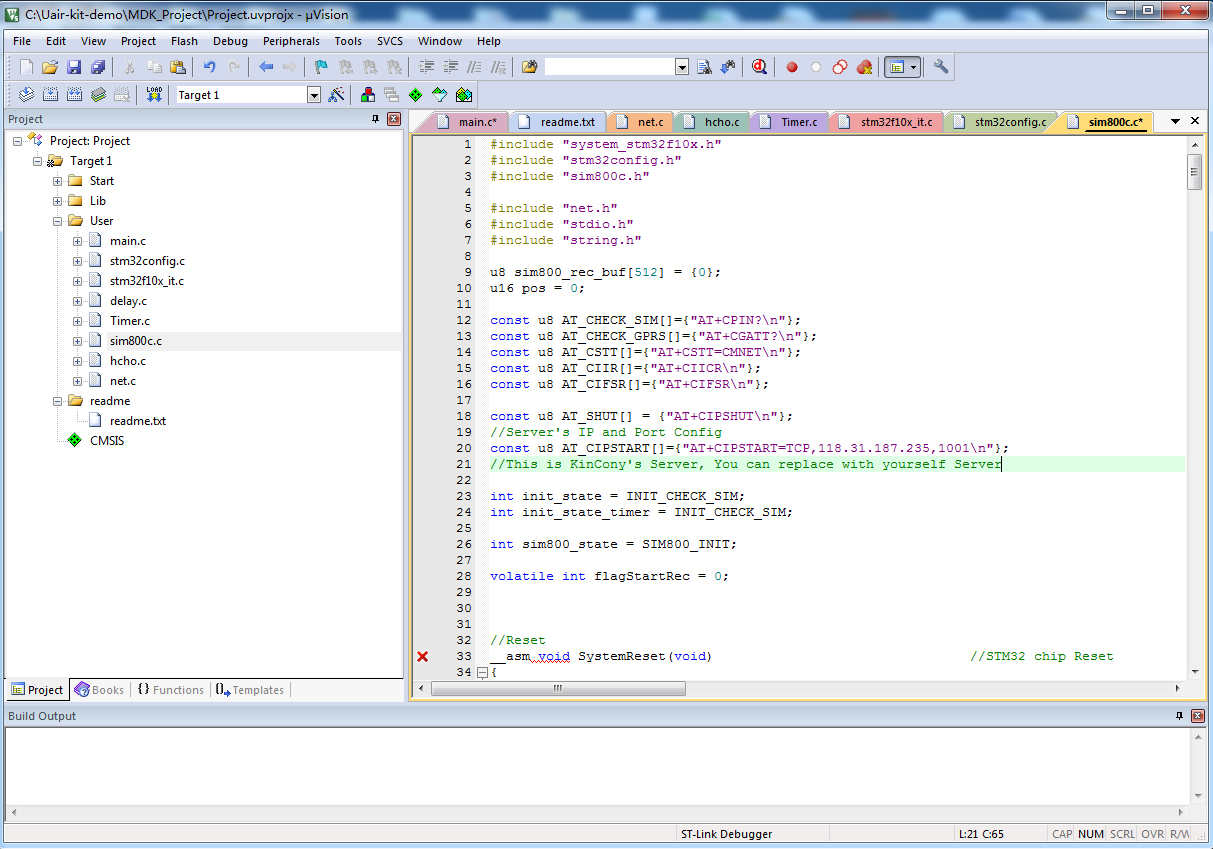

On the development board, we use the sim800c communication module as the core from the company of SIMCOM, which the drive code is in the file of sim800.c. For the communication part, it’s mainly the IP address and port of the specified server. If you need to send data to your own cloud server, just modify your server IP address and port in line 20 program code, the corresponding code is also annotated. At the same time, on the server, you need to write a Socket communication server-side program. In the early stage, it is suggested to use the network debugging assistant to set the parameters directly so that the communication can be realized. If you write the host computer program, you can also use the socket control provided by the development tool, such as: VC, VB, Java, Delphi, C++ builder etc., all provide the corresponding communication components, so that the development work is very convenient.

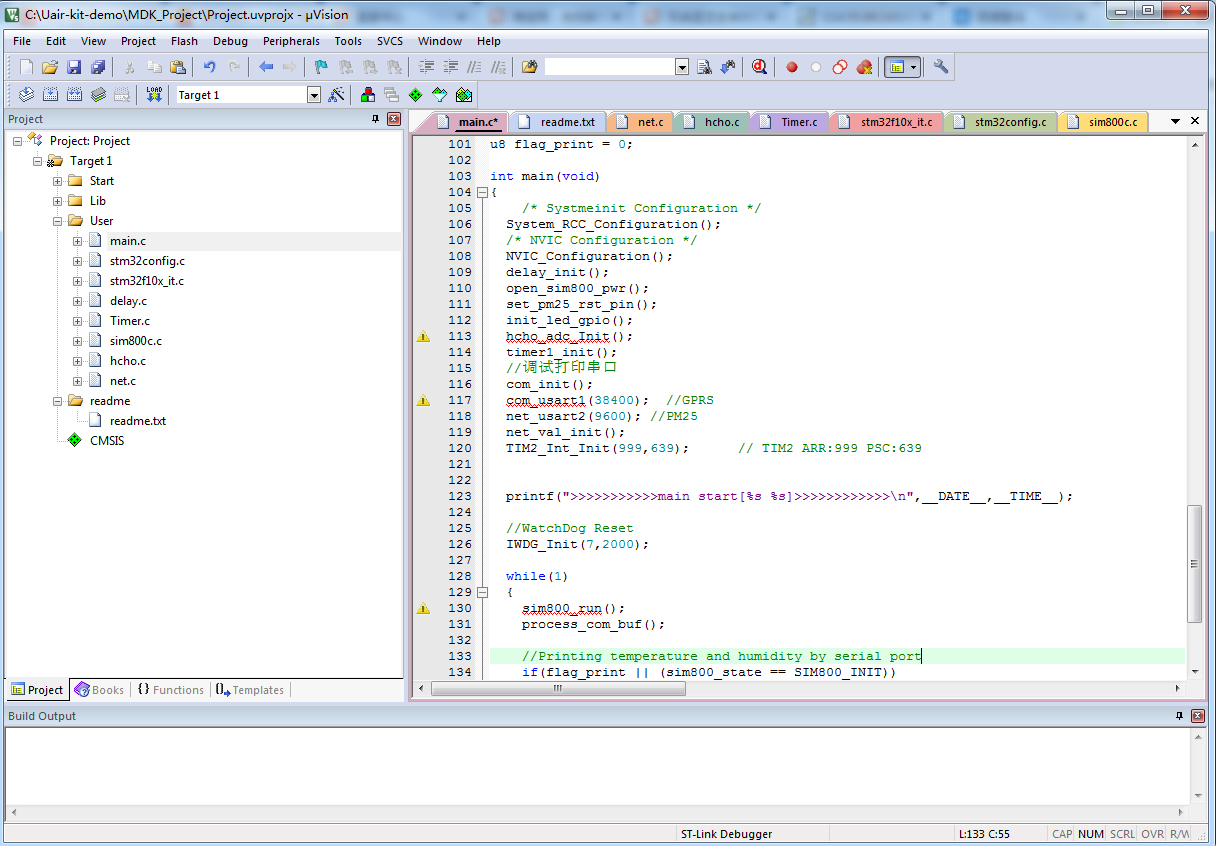

This is the subroutine of low-level temperature and humidity acquisition; it converts the corresponding Analog semaphore into Digital quality and then transmits to the server.

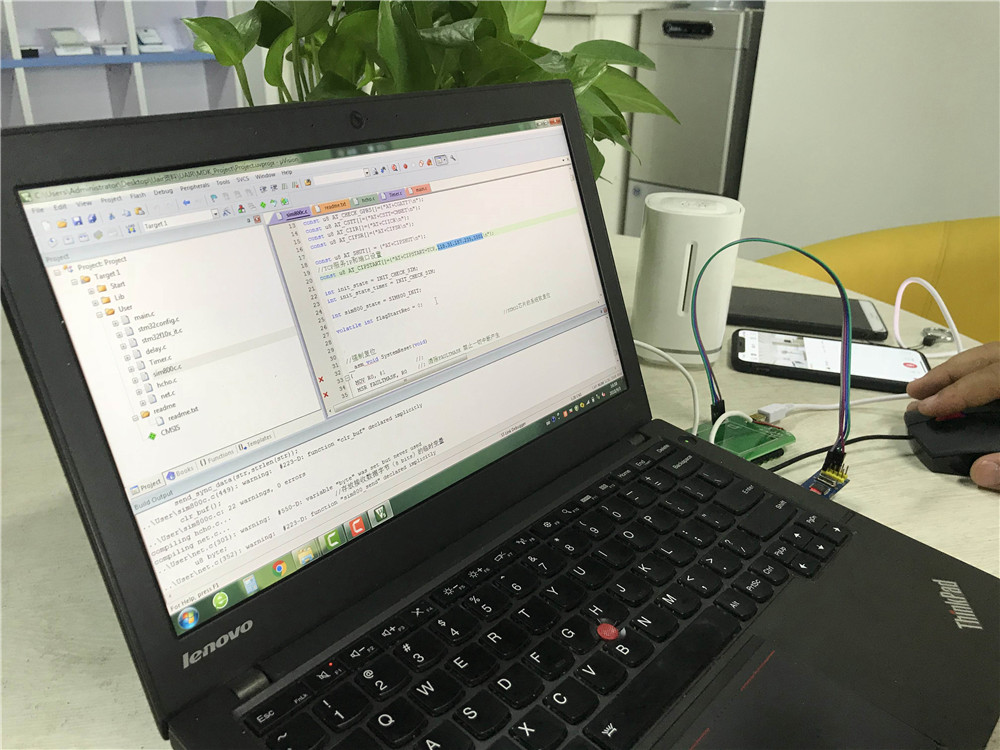

After the program modification is completed, we connect the downloader with the development board through the USB port, and directly in the KEIL software, we can carry on the simulation operation or the on-line burning program operation.

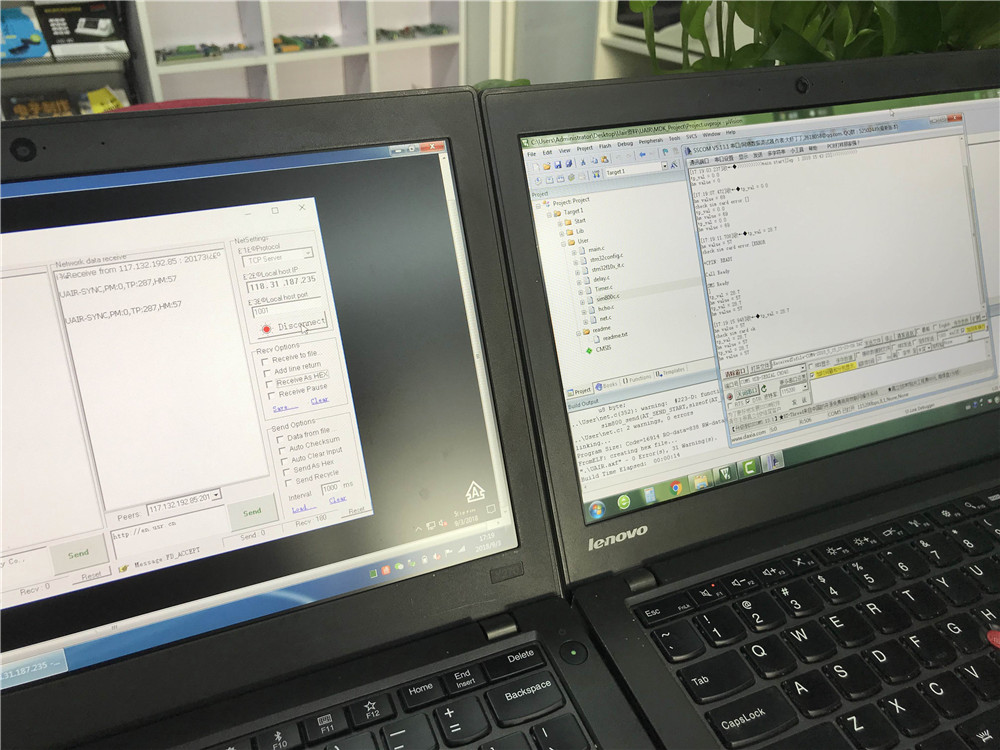

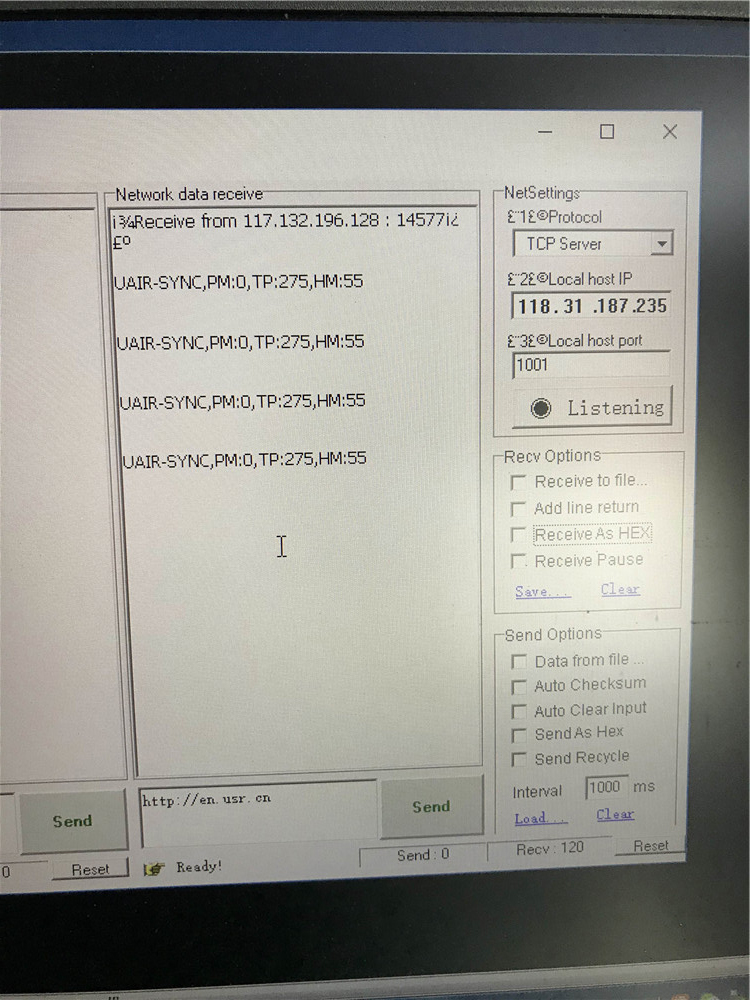

After finishing the programming, we use two computers to test, the left laptop is connected to the cloud server of Kincony Company, and we open a network debugging assistant window on the server to receive data from the client. The right notebook computer is for programming the software.

The server IP and port set on the cloud server are: 118.31. 187.235 and 1001, which is the parameter setting in the source program in the KEIL software, and the settings in the two computers must be the same.

In order to make developers understand the information of the development board in real time, we feedback the current status of the whole development board through the serial port. The developer can connect the serial port on the development board to the PC terminal. Check the working status of the circuit board in real time, such as the connection of GPRS network, the frequency and value of temperature and humidity data acquisition, etc.

On the right screen, you can see that new temperature and humidity values are collected every 10 seconds. Meanwhile the GPRS wireless connections are established, and data is transmitted. On the left screen, you can see data values that are constantly being reported by the client.

This is real-time serial port detection, reflecting the current work of the development board.

We have a complete set of software and hardware development manuals for developers. If you have any questions, you are welcome to contact us. Our engineers will provide you with R & D level technical support.

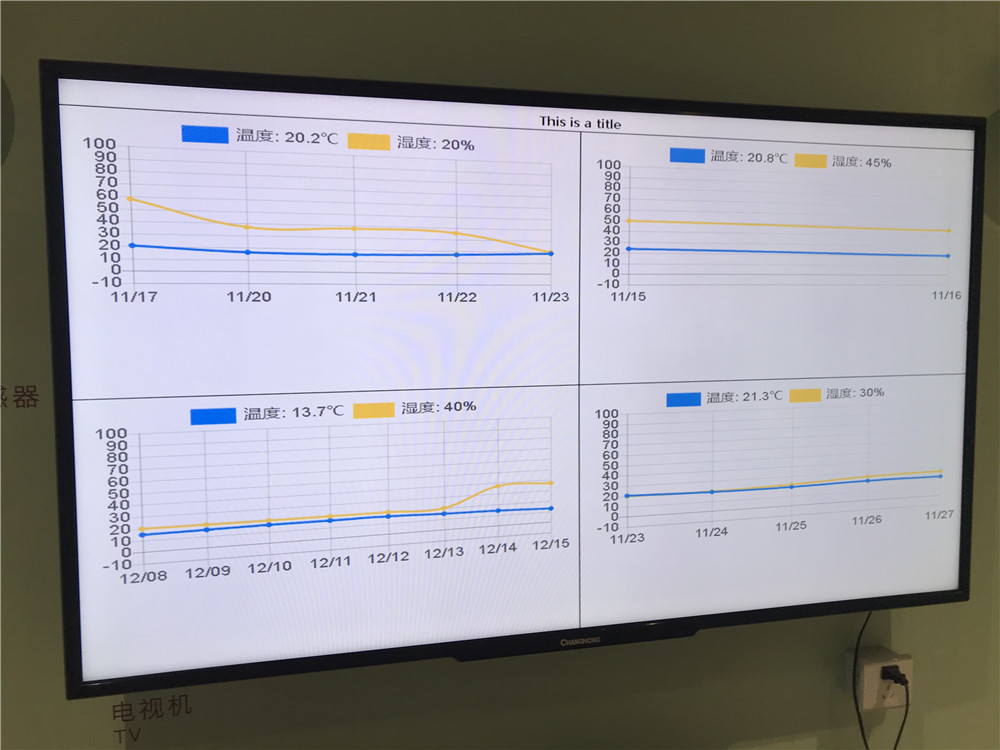

This is a development example of real-time display of temperature and humidity data through a TV (the server-side software is required to build in advance)

This is the plastic shell matching the development board.

These are the result of installing the development board into the shell.